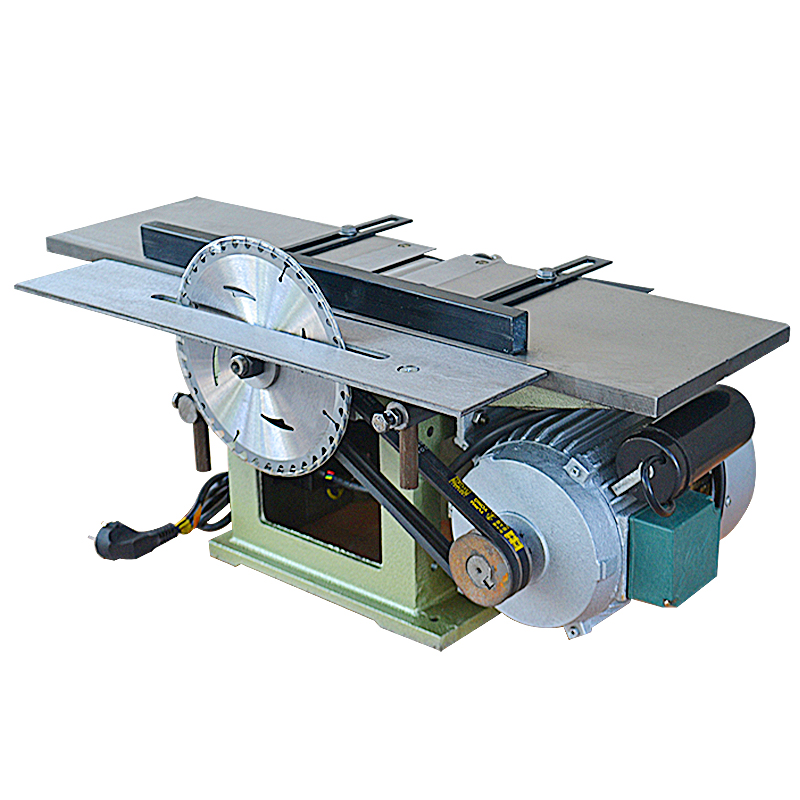

Woodworking planer is used to create boards that is parallel and an even thickness throughout their length making it flat on theupper surface.

A machine consists of three elements, a cutter head which contains the cutting knives, a set of in feed and out feed rollers which draw the board through the machine and a table which is adjustable to control the depth of thickness of the board.

We provide 2 models of woodworking thicknesser planers for your choice.

WTP120 Feature.

Loadable saw blade: 230mm (9 inch)

Thickness of cutter: 80mm

Planing depth: 0.8mm

Planing width: 120mm

Table size: 560*255mm

Saw table can not be lifted

Package size: 580*300*235mm

Gross weight: 38kg

Voltage: 220V

HZ:50Hz

Wattage: 1.3KW

WTP150 Features.

Loadable saw blade: 250mm (10 inch)

Thickness of cutter: 80mm

Planing depth: 0-3mm

Planing width: 150mm

Table size: 680*300mm

Saw table can be lifted

Package size: 710*310*300mm

Gross weight: 55kg

Voltage: 220V

HZ:50Hz

Wattage: 1.5KW

Advantages.

1.Machine is equipped with an upgraded version of the motor, the motor cooling effect is good, the power is higher than the ordinary motor.

2. Worktable is made of high-strength operation and has high strength and no deformation.

3. The structure is stable and durable, precision saw card, stable material.

4. Emergency stop button, you can stop the machine immediately in an emergency.

5. The cutting is smooth and smooth, and the cutting surface is smoother.

6. High-speed and high-precision machining can be realized, which can greatly improve processing efficiency and reduce processing costs.

7. It can realize planing, planing and table processing, which can meet different processing requirements.

8. Automatic control can be realized, which can improve the processing quality and reduce the processing error.

9. Adopt high-tech control system, which can ensure operation safety and reduce operation danger.

10.Adopt energy-saving technology, which can save energy and reduce energy consumption.

Post time: May-22-2023